Description

The Avina Export Group is capable of supplying zinc ingots with dimensions and technical specifications according to the standards and tables below. Zinc ingots are used in the steel industry for galvanizing to enhance the corrosion resistance of steel. They are also utilized in the production of various alloys, especially brass and other zinc alloys, as well as in the manufacturing of batteries and other electrical equipment.

- What is Zinc ingot?

- What are the technologies used in Zinc ingot production?

- What are the advantages of Zinc ingot?

- What are the standards for Zinc ingot?

- What do you know about Iranian Zinc ingot?

- To which countries is Iranian Zinc ingot exported?

- What are the advantages of Iranian Zinc ingot compared to their competitors?

________________________________________________________

1. What is zinc ingot?

A zinc ingot is a solid block of pure zinc metal that has been cast into a specific shape, usually a rectangular or trapezoidal form, for ease of storage, handling, and further processing. Zinc ingots are produced by refining zinc ore, which is typically found in the form of zinc sulfide (also known as sphalerite). The ingots are used as a raw material in various industries.

Key Characteristics of Zinc Ingots:

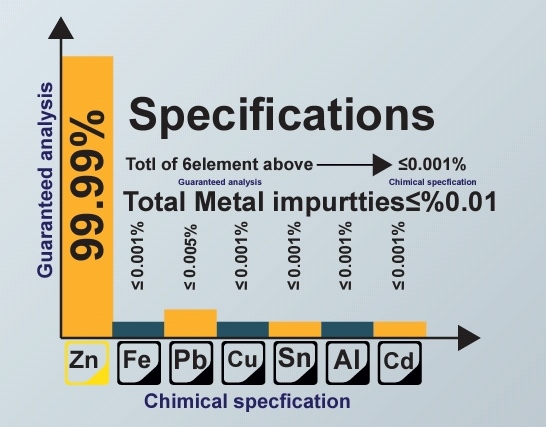

- Purity: Zinc ingots are typically very pure, often with a zinc content of 99.9% or higher. The purity of the zinc can vary depending on the intended use and the refining process.

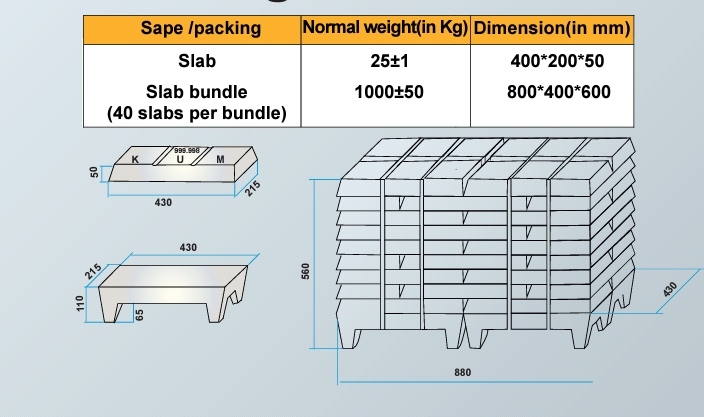

- Shape and Size: Zinc ingots come in various sizes and shapes, with standard weights ranging from a few kilograms to several hundred kilograms, depending on the manufacturer and specific requirements.

Production Process:

- Mining: Zinc is primarily extracted from zinc sulfide ores through mining.

- Concentration: The ore is crushed and ground, and the zinc sulfide is separated from other materials through a process called froth flotation.

- Roasting: The concentrated zinc sulfide is heated in the presence of oxygen to produce zinc oxide and sulfur dioxide.

- Reduction: Zinc oxide is then reduced to zinc metal by heating it with carbon or by electrolytic processes.

- Refining: The zinc metal is refined to remove impurities.

- Casting: The purified zinc is cast into ingots for storage and transportation.

Applications of Zinc Ingots:

- Galvanization: One of the most common uses of zinc ingots is in the galvanization process, where steel or iron is coated with a thin layer of zinc to protect against corrosion.

- Alloy Production: Zinc is an essential component in many alloys, such as brass (an alloy of copper and zinc) and zinc-aluminum alloys.

- Die Casting: Zinc ingots are used in die casting to produce complex metal parts for the automotive, electronics, and household appliance industries.

- Chemical Production: Zinc is used in the production of various chemicals, including zinc oxide, which is used in rubber, ceramics, and pharmaceuticals.

- Battery Production: Zinc is a key material in the production of batteries, including zinc-carbon and zinc-air batteries.

- Construction and Roofing: Zinc is used in the construction industry for roofing materials and other building components due to its corrosion resistance and durability.

Benefits of Zinc:

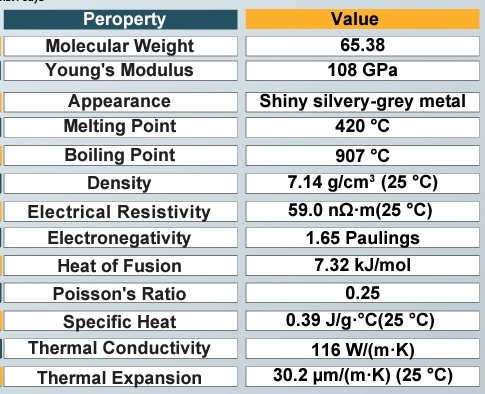

- Corrosion Resistance: Zinc’s ability to resist corrosion makes it ideal for protecting other metals from rust and degradation.

- Malleability and Ductility: Zinc is relatively easy to work with, making it suitable for forming into various shapes and products.

- Recyclability: Zinc can be recycled without losing its physical or chemical properties, making it a sustainable material choice.

Zinc ingots are a versatile and essential raw material used across multiple industries, offering durability, protection, and functionality in various applications.

2. What are the technologies used in Zinc ingot production?

Zinc ingot production involves several technologies and processes, each designed to extract and purify zinc from its ores or secondary materials. The primary methods are:

1. Roasting and Sintering

- Roasting: Zinc sulfide ores, such as sphalerite, are roasted in the presence of oxygen to produce zinc oxide (ZnO) and sulfur dioxide (SO₂).

- Sintering: The fine zinc oxide particles are sintered (heated to below their melting point) to agglomerate them, making them easier to handle in the subsequent reduction process.

2. Electrolytic Process (Hydrometallurgical Process)

- Leaching: Zinc oxide is leached with sulfuric acid to produce a zinc sulfate solution.

- Purification: The zinc sulfate solution is purified by removing impurities like iron, copper, and cadmium through various precipitation and filtration steps.

- Electrolysis: The purified zinc sulfate solution undergoes electrolysis, where electric current is passed through the solution to deposit zinc on cathodes. The deposited zinc is then melted and cast into ingots.

3. Pyrometallurgical Process (Imperial Smelting Process)

- Sintering: Similar to the roasting step, but here the feed is a mixture of zinc and lead concentrates.

- Reduction: The sintered material is reduced in a blast furnace with coke (carbon) to produce zinc vapor and lead bullion.

- Condensation: The zinc vapor is then condensed into liquid zinc, which is cast into ingots. Lead is separated from the bottom of the furnace.

4. Waelz Kiln Process (for Zinc from Secondary Materials)

- Feed: This process is mainly used for treating zinc-containing secondary materials, like Electric Arc Furnace (EAF) dust or zinc-containing residues.

- Reduction and Volatilization: The material is fed into a rotating kiln, where it is heated and reduced with coke or coal. Zinc is volatilized and then condensed.

- Recovery: The recovered zinc is further refined and cast into ingots.

5. Vacuum Distillation

- Distillation: This process is often used for refining zinc to high purity levels. Crude zinc is heated in a vacuum, and the zinc vapor is collected and condensed in a separate chamber, leaving impurities behind.

6. Thermal Decomposition

- Decomposition: Certain zinc compounds, like zinc carbonate or zinc hydroxide, can be decomposed thermally to produce zinc oxide, which is then reduced to metallic zinc.

These technologies are often combined or adapted depending on the specific raw material being processed and the desired quality of the zinc ingot.

3. What are the advantages of Zinc ingot?

Zinc ingots offer several advantages that make them valuable in various industries. Here are some key benefits:

1. Corrosion Resistance

- Advantage: Zinc has excellent corrosion resistance, particularly in atmospheric conditions. This makes it an ideal material for galvanizing steel and other metals to protect them from rust and corrosion.

- Applications: Widely used in the automotive, construction, and infrastructure industries to coat steel structures, bolts, and automotive parts.

2. Versatility

- Advantage: Zinc ingots can be alloyed with other metals like aluminum, copper, and magnesium to produce a wide range of zinc alloys. These alloys have varied properties, such as improved strength, ductility, and wear resistance.

- Applications: Used in die casting, the manufacture of components for automotive and electrical industries, and in the production of brass.

3. Malleability and Ductility

- Advantage: Zinc is relatively easy to shape, mold, and cast due to its malleability and ductility. This makes it an excellent material for manufacturing complex shapes and components.

- Applications: Die casting of automotive parts, toys, and various small appliances.

4. Recyclability

- Advantage: Zinc is highly recyclable without losing its physical and chemical properties. Recycling zinc reduces energy consumption and conserves natural resources.

- Applications: Recycled zinc is commonly used in the production of new zinc ingots, alloys, and galvanizing processes.

5. Cost-Effectiveness

- Advantage: Zinc is relatively abundant and affordable compared to other non-ferrous metals like copper and nickel. Its cost-effectiveness makes it a preferred choice for many industrial applications.

- Applications: Used extensively in the production of galvanized steel, die-cast products, and in the chemical industry.

6. Low Melting Point

- Advantage: Zinc has a relatively low melting point (419.5°C), which reduces energy consumption during melting and casting processes.

- Applications: Ideal for die casting, where low melting temperatures can produce complex and high-precision parts.

7. Environmental Benefits

- Advantage: Zinc’s ability to protect steel from corrosion significantly extends the lifespan of products, reducing the need for frequent replacements and thereby conserving resources.

- Applications: Long-lasting galvanized steel structures, energy-efficient manufacturing processes.

8. Biocompatibility

- Advantage: Zinc is non-toxic and plays an essential role in biological systems, making it safe for applications in food and healthcare industries.

- Applications: Used in zinc-based supplements, medical devices, and food packaging.

9. Electrical Conductivity

- Advantage: While not as conductive as copper, zinc has sufficient electrical conductivity to be used in certain electrical applications.

- Applications: Used in battery production, particularly in alkaline and zinc-carbon batteries.

10. Surface Coating and Aesthetic Appeal

- Advantage: Zinc can be easily coated or finished to enhance its appearance and functionality. It can be polished, painted, or treated for various visual effects.

- Applications: Architectural applications, decorative items, and consumer goods.

These advantages make zinc ingots a vital material in numerous industries, contributing to their widespread use in everything from construction to consumer products.

4. What are the standards for Zinc ingot?

Zinc ingots are subject to various standards that specify their chemical composition, physical properties, and quality. These standards ensure consistency in the quality of zinc ingots used across different industries, such as galvanizing, die casting, and alloy production. Here are some of the key standards for zinc ingots:

1. ASTM B6

- Title: Standard Specification for Zinc.

- Details:

- This standard specifies the requirements for the chemical composition and physical properties of zinc ingots.

- Grades: There are various grades, including High Grade (HG), Special High Grade (SHG), and Prime Western (PW).

- Chemical Composition:

- SHG: Minimum of 99.995% zinc.

- HG: Minimum of 99.99% zinc.

- PW: Minimum of 98.5% zinc.

- Impurities: Limits for elements like lead, cadmium, iron, and others are specified.

2. ISO 752

- Title: Zinc ingots.

- Details:

- Specifies the requirements for zinc ingots used for remelting.

- Defines similar grades to ASTM B6, such as SHG and HG, with comparable purity levels.

- Emphasizes chemical composition and permissible impurities.

3. GB/T 470-2008 (China)

- Title: Zinc Ingot.

- Details:

- Chinese standard for zinc ingots.

- Grades: Includes 0A, 1A, and 2A.

- Chemical Composition:

- 0A: Minimum of 99.995% zinc.

- 1A: Minimum of 99.99% zinc.

- 2A: Minimum of 99.95% zinc.

- Specifies maximum allowable impurities for elements like lead, cadmium, iron, and tin.

4. JIS H 2107 (Japan)

- Title: Zinc Ingots.

- Details:

- Japanese standard for zinc ingots.

- Grades: SHG, HG, and others.

- Emphasizes purity and limits on specific impurities like lead, cadmium, and iron.

5. EN 1179 (European Standard)

- Title: Zinc and zinc alloys – Primary zinc.

- Details:

- European standard specifying the grades of primary zinc, including SHG and HG.

- Chemical Composition:

- SHG: Minimum of 99.995% zinc.

- HG: Minimum of 99.99% zinc.

- Defines allowable impurities similar to other international standards.

6. LME (London Metal Exchange)

- Title: LME Zinc Ingot.

- Details:

- The LME has specific standards for zinc ingots traded on the exchange.

- These ingots typically conform to SHG specifications with a minimum of 99.995% zinc.

- Must meet physical specifications for shape and weight to be eligible for trading.

General Requirements

- Shape: Typically trapezoidal, for easy stacking.

- Weight: Usually around 25 kg per ingot, though it can vary.

- Surface: Free from visible impurities, corrosion, and oxidation.

These standards ensure that zinc ingots used in various industries meet the required purity levels and are free from harmful impurities that could affect their performance in end-use applications.

5. What do you know about Iranian Zinc ingot?

Iran is one of the significant producers of zinc in the Middle East, and its zinc ingots are known for being competitive in both quality and price. Here’s an overview of Iranian zinc ingots:

Production and Reserves

- Reserves: Iran has substantial zinc reserves, with major deposits located in the provinces of Zanjan, Yazd, and Kerman. The Mehdiabad, Angouran, and Kushk mines are among the key sources of zinc ore.

- Production: Iran’s zinc industry has grown over the years, with several smelters and refineries producing zinc ingots for both domestic consumption and export. The production capacity is supported by these extensive reserves and the availability of infrastructure.

Quality and Standards

- Purity: Iranian zinc ingots typically conform to international standards, such as ASTM B6 and ISO 752. They are often produced in different grades, including Special High Grade (SHG) with 99.995% zinc purity, High Grade (HG) with 99.99%, and Prime Western (PW) with lower purity.

- Standards Compliance: Iranian producers ensure that their zinc ingots meet the required chemical composition and physical properties, making them suitable for various industrial applications.

Applications

- Domestic Use: Zinc ingots produced in Iran are used extensively in the galvanizing industry, alloy production, and die casting. The construction sector, automotive industry, and manufacturing of electrical components are key domestic consumers.

- Exports: Iranian zinc ingots are exported to various countries, including those in Asia, Europe, and the Middle East. The competitive pricing, due to lower production costs, makes them attractive in the international market.

Key Producers

- National Iranian Lead and Zinc Company (NILZ): One of the largest producers of zinc ingots in Iran, NILZ operates the Angouran mine and a smelter in Zanjan. They produce zinc ingots in various grades and have a significant share in both domestic and export markets.

- Bafgh Zinc Smelting Company: Another major player, located in Yazd province, known for producing high-quality zinc ingots that meet international standards.

- Kerman Zinc Industry Co.: Known for producing zinc ingots from the Kushk mine, this company also plays a significant role in Iran’s zinc market.

Economic Impact

- Export Revenues: The export of zinc ingots is an important source of revenue for Iran. The country’s strategic location and access to both Asian and European markets facilitate trade.

- Domestic Economy: The zinc industry contributes to local economies, particularly in mining regions, by providing jobs and supporting ancillary industries.

6. To which countries is Iranian Zinc ingot exported?

Iranian zinc ingots are exported to several countries across different regions. The main destinations for Iranian zinc include:

- China: One of the largest importers of zinc globally, China imports significant quantities of zinc ingots from Iran.

- India: Another major importer of zinc, India sources a considerable amount of zinc from Iran.

- Turkey: Turkey is a key trading partner of Iran and imports zinc ingots for its industrial needs.

- United Arab Emirates (UAE): The UAE, being a regional trading hub, imports zinc ingots from Iran for domestic use and re-export.

- South Korea: South Korea is another important market for Iranian zinc ingots, especially for use in its manufacturing industries.

- Europe: Some European countries, including Italy and Germany, import zinc ingots from Iran, although trade relations can be influenced by international sanctions and market conditions.

- Southeast Asia: Countries like Malaysia and Indonesia also import Iranian zinc ingots, driven by their growing industrial sectors.

- What are the advantages of Iranian Zinc ingot compared to their competitors?

Iranian zinc ingots have several advantages that make them competitive in the global market:

- High Purity and Quality: Iranian zinc ingots are known for their high purity, often meeting or exceeding international standards. This makes them desirable for various industrial applications, including galvanization, alloy production, and manufacturing.

- Cost Competitiveness: Iran’s relatively low production and labor costs enable it to offer zinc ingots at competitive prices. This cost advantage makes Iranian zinc an attractive option for buyers looking to reduce procurement costs without compromising quality.

- Abundant Raw Material Supply: Iran has significant zinc reserves, which ensures a steady supply of raw materials for zinc production. This reliability in supply helps maintain consistent production levels and meet export demands.

- Strategic Geographic Location: Iran’s strategic location between Europe and Asia provides logistical advantages. It allows for shorter and more cost-effective shipping routes to key markets in Asia, Europe, and the Middle East, reducing transportation costs and delivery times.

- Advanced Production Facilities: Iran has invested in modernizing its zinc production facilities, ensuring that the manufacturing process is efficient and meets international environmental and quality standards. This results in a high-quality product that is competitive globally.

- Government Support and Incentives: The Iranian government actively supports the mining and metals industry, including zinc production, through various incentives, subsidies, and policies. This support helps the industry remain competitive on the global stage.

- Diverse Export Markets: Iran’s zinc ingot exports are diversified across several regions, reducing dependency on any single market and allowing for greater stability in export revenues.

- Sustainability Initiatives: Some Iranian zinc producers are increasingly adopting sustainable practices, which can appeal to environmentally conscious buyers looking for responsibly sourced materials.

These advantages help Iranian zinc ingots maintain a strong position in the global market despite the challenges posed by international competition and geopolitical factors.