Description

_______________________________________________________________

1. What is wire rod?

1. Wire rod is a hot-rolled steel product with a round cross-section. It is typically produced from steel billets and is wound into coils. Wire rod is used as the raw material for a variety of products, including wire, nails, screws, springs, and other industrial products.

2. The production process involves heating a steel billet, rolling it through a series of mills to reduce its diameter, and finally winding it into coils. The diameter of wire rod usually ranges from 5.5 mm to 16 mm, depending on the specific requirements.

3. Wire rod is commonly used in the construction, automotive, and manufacturing industries, where it serves as the basis for making wire products of various types and sizes.

2. What are the technologies used in wire rod production?

Wire rod production involves several advanced technologies to ensure the production of high-quality and uniform wire rods. Here are some of the key technologies used in the process:

1. Continuous Casting

- Process: Continuous casting is the process where molten steel is solidified into semi-finished billets, which are then used as the raw material for wire rod production. This method ensures a consistent quality of steel and reduces the number of defects.

2. Heating Furnace

- Process: Billets are heated to the required rolling temperature in a reheating furnace. Technologies like walking beam furnaces are commonly used, which provide uniform heating and energy efficiency.

3. Rolling Mills

- Process: Rolling mills are used to reduce the size of the billets into wire rods through a series of rollers. Advanced rolling technologies include:

- Tandem Rolling: Multiple rolling stands work in sequence to reduce the billet’s diameter gradually.

- No-Twist Mills: Ensure that the wire rod is produced without any torsion, improving the final product’s quality.

- High-Speed Rolling Mills: Enable higher production rates while maintaining quality.

4. Controlled Cooling (Stelmor Process)

- Process: After rolling, the wire rod undergoes controlled cooling to achieve the desired mechanical properties. The Stelmor process, a popular cooling technology, uses conveyor belts and air blowers to control the cooling rate, ensuring uniformity in the microstructure.

5. Surface Treatment

- Process: Surface defects and scales formed during rolling are removed through various methods like pickling or shot blasting. This ensures a smooth surface finish for the wire rods.

6. Coiling and Packaging

- Process: The finished wire rod is coiled into large coils for easy handling and transportation. Modern coiling machines ensure that the coils are uniform and compact, reducing the risk of tangling during transport.

7. Automation and Quality Control

- Technology: Modern wire rod production lines are equipped with advanced automation systems for real-time monitoring and control of the production process. These systems help in maintaining consistent quality, optimizing energy use, and reducing production costs.

8. Descaling Technology

- Process: Wire rods are often passed through mechanical descaling or chemical pickling processes to remove oxides and scale, improving the surface quality before further processing.

These technologies work together to produce high-quality wire rods that meet the stringent requirements of various industries.

3. What are the advantages of wire rod?

Wire rod, a hot-rolled steel product produced in coils, has several advantages that make it a versatile material used across various industries. Here are some of the key advantages:

- High Strength and Durability: Wire rod is known for its high tensile strength and durability, making it ideal for use in construction, automotive, and industrial applications.

- Versatility: It can be used to produce a wide range of products, including wires, springs, fasteners, cables, and more. This versatility makes it a critical raw material in manufacturing.

- Good Weldability: Wire rod is often used in welding applications due to its good weldability, which ensures strong and reliable joints.

- Flexibility: It can be easily formed into different shapes and sizes, allowing for precise manufacturing of components.

- Cost-Effectiveness: Wire rod is generally cost-effective due to its wide availability and the efficiency of its production process. This makes it an economical choice for large-scale manufacturing.

- Corrosion Resistance: Depending on the alloy and coating, wire rod can offer good resistance to corrosion, which is important in applications exposed to harsh environments.

- Ease of Processing: The material can be processed using various techniques like drawing, coiling, and cutting, allowing for customization according to specific needs.

- Lightweight: Despite its strength, wire rod is relatively lightweight, which is beneficial in applications where weight is a critical factor, such as in the automotive and aerospace industries.

These advantages make wire rod a crucial material in numerous sectors, including construction, manufacturing, and telecommunications.

4. What are the standards for wire rods?

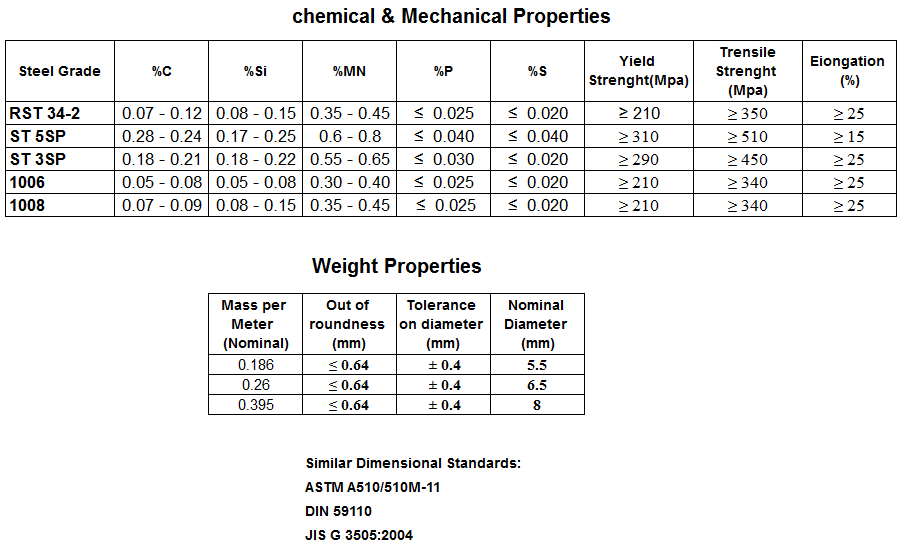

Standards for wire rods can vary depending on the application, material, and regional regulations. However, the most common standards include those set by organizations such as ASTM (American Society for Testing and Materials), ISO (International Organization for Standardization), and EN (European Standards). Here’s an overview:

1. Material Standards

- ASTM A510: Covers carbon steel wire rods used for manufacturing springs, wire rope, and other applications. It specifies chemical composition, mechanical properties, and quality control measures.

- ASTM A706: Covers low-alloy steel wire rods used for reinforced concrete, with specific standards for weldability and bending properties.

- ISO 16120: Specifies requirements for non-alloy steel wire rods for drawing and/or cold rolling.

- EN 10016: European standard for non-alloy steel wire rods, outlining dimensions, tolerances, mechanical properties, and other characteristics.

2. Dimensional Standards

- ASTM A510M: Specifies dimensional tolerances for wire rods, including diameter, ovality, and length.

- EN 10017: Focuses on the dimensions and tolerances of non-alloy steel wire rods in the European market.

3. Mechanical Properties

- Tensile strength, yield strength, elongation, and hardness are typically specified, depending on the application.

- ASTM, ISO, and EN standards usually detail these properties.

4. Surface Quality

- Wire rods must be free from surface defects such as cracks, scales, or rust.

- Surface finish standards ensure that the wire rod is suitable for further processing, such as drawing or rolling.

5. Coating and Corrosion Resistance

- Standards may specify coatings such as galvanization for corrosion resistance.

- ASTM A641: Covers zinc-coated (galvanized) carbon steel wire rods for mechanical applications.

6. Testing and Quality Control

- Standards often include specific tests to ensure compliance, including tensile tests, bending tests, and chemical analysis.

7. Applications and End Use

- Different standards apply based on the intended application, whether for construction, automotive, electrical, or other industries.

8. Packaging and Labeling

- Standards may also cover how wire rods are packaged, labeled, and transported to ensure traceability and quality during shipping.

- Compliance with these standards ensures that wire rods meet the necessary safety, performance, and quality requirements for various industrial applications.

5. What do you know about Iranian wire rod?

- Iranian wire rod, like wire rods from other countries, is a product used in various industrial applications, including construction, manufacturing, and automotive sectors. Iran has a substantial steel industry, and wire rod production is a significant part of it. Here are some key points about Iranian wire rod:

1. Production and Manufacturers

- Major Producers: Iran has several large steel producers that manufacture wire rods, including Mobarakeh Steel Company, Khuzestan Steel Company, and Esfahan Steel Company.

- Production Capacity: Iran has a significant production capacity for wire rods, which is part of its broader steel production industry. The country ranks among the top steel producers globally.

- Grades and Types: Iranian wire rods are produced in various grades and types, including carbon steel, low-alloy steel, and high-carbon steel. These can be used for different applications such as welding, drawing, and reinforcing concrete.

2. Standards and Quality

- Compliance with International Standards: Iranian wire rods generally comply with international standards such as ASTM, ISO, and EN, making them suitable for export to various markets.

- Quality Control: Iranian manufacturers typically adhere to strict quality control measures to ensure that their wire rods meet the required mechanical properties, dimensional tolerances, and surface quality.

3. Applications

- Construction: Used in the production of reinforced concrete structures, rebar, and other construction materials.

- Automotive: Used in the manufacturing of parts such as springs, fasteners, and tire cords.

- Industrial: Used in wire drawing, welding, and the production of nails, screws, and other hardware.

4. Export Market

- Export Destinations: Iranian wire rods are exported to various countries in the Middle East, Asia, and Europe. The country’s strategic location allows it to serve a wide range of markets.

- Challenges and Opportunities: While Iran’s steel industry faces challenges due to trade restrictions, it continues to export to certain regions, leveraging competitive pricing and quality.

5. Pricing

- Competitive Pricing: Iranian wire rods are often competitively priced due to lower production costs and government support for the steel industry.

- Market Influence: The pricing of Iranian wire rods can be influenced by global steel prices, domestic demand, and economic policies.

6. Technological Advancements

- Modernization Efforts: Iranian steel manufacturers have been investing in modernizing their production facilities, which has led to improvements in the quality and variety of wire rods produced.

7. Regulatory Environment

- Government Support: The Iranian government supports the steel industry through policies aimed at boosting production and export.

8. Environmental Considerations

- Sustainability Efforts: Like many steel producers globally, Iranian companies are increasingly focused on reducing their environmental impact, including efforts to minimize carbon emissions and improve energy efficiency in production.

- Iran’s wire rod industry plays a crucial role in its economy, both for domestic use and exports, contributing to the broader steel sector’s growth.

6. To which countries is Iranian wire rod exported?

- Iranian wire rod is exported to several countries, primarily in the Middle East, Asia, and occasionally in Europe and Africa. The export destinations are influenced by factors such as geopolitical relations, trade agreements, and demand in specific markets. Here’s a breakdown of the key export markets for Iranian wire rods:

1. Middle East

- Iraq: As a neighboring country, Iraq is one of the significant importers of Iranian steel products, including wire rods. The construction boom and infrastructure development in Iraq drive demand.

- Afghanistan: Another neighboring country, Afghanistan imports Iranian wire rods for use in construction and infrastructure projects.

- Turkey: Turkey is both a competitor and a market for Iranian steel products. Depending on trade relations and market conditions, Turkish companies may import Iranian wire rods.

- United Arab Emirates: The UAE imports Iranian wire rods for use in its construction sector, although trade can be influenced by political relations.

2. Asia

- China: China is a major player in the global steel market and imports steel products, including wire rods, from various countries, including Iran. However, China’s own large steel industry means that imports are often opportunistic based on pricing and demand.

- India: India, another major steel producer, imports Iranian wire rods, particularly when they are competitively priced or when specific grades are required.

- Pakistan: As a neighboring country, Pakistan imports Iranian wire rods for its construction and manufacturing sectors.

3. Europe

- Italy: Italy has imported Iranian steel products, including wire rods, although European imports are subject to strict regulations.

- Spain: Like Italy, Spain has been a market for Iranian steel products, with imports influenced by competitive pricing and specific demands.

4. Africa

- North Africa: Countries like Egypt and Algeria have imported Iranian wire rods, primarily for use in construction and infrastructure development. Trade with these countries can vary based on regional demand and trade relations.

5. CIS Countries

- Azerbaijan: As a neighboring country with strong trade ties to Iran, Azerbaijan imports wire rods for use in construction and industrial applications.

- Armenia: Armenia also imports Iranian wire rods, benefiting from close proximity and established trade routes.

6. South East Asia

- Thailand: Thailand is a market for Iranian wire rods, especially when prices are favorable and when specific grades are required.

- Malaysia: Malaysia imports wire rods from Iran, often driven by construction demand and competitive pricing.

7. Latin America (Occasionally)

- Although less common, some Latin American countries have imported Iranian wire rods. However, this is often limited due to logistical challenges and competition from other suppliers.

Factors Influencing Exports

- Pricing Competitiveness: Iranian wire rods are often competitively priced, making them attractive in markets where cost is a significant factor.

- Geopolitical Relations: Trade relations and geopolitical factors heavily influence which countries import Iranian wire rods.

- Despite the challenges posed trade restrictions, Iran continues to find markets for its wire rods through competitive pricing and strategic trade relationships.

7. What are the advantages of Iranian wire rod compared to their competitors?

- Iranian wire rods have several advantages compared to their competitors, particularly in terms of cost, geographic location, and production capacity. Here’s a breakdown of these advantages:

1. Competitive Pricing

- Lower Production Costs: Iran benefits from relatively low energy costs, particularly in natural gas, which is a significant input in steel production. This allows Iranian wire rods to be priced competitively in the global market.

- Government Support: The Iranian government provides support to the steel industry, including subsidies and favorable policies, which help keep production costs low and enhance the competitiveness of Iranian wire rods.

2. Strategic Geographic Location

- Proximity to Key Markets: Iran’s location near major markets in the Middle East, Asia, and Europe reduces transportation costs and delivery times, giving it an advantage over competitors located farther away.

- Access to Land and Sea Routes: Iran has access to key land routes to neighboring countries and strategic sea routes via the Persian Gulf, facilitating efficient export logistics.

3. High Production Capacity

- Large Steel Industry: Iran is one of the largest steel producers in the world, with significant capacity for wire rod production. This scale allows Iranian producers to meet large orders and offer a consistent supply, which is attractive to buyers.

- Diverse Product Range: Iranian steel producers offer a wide range of wire rod grades and specifications, catering to various industries and applications, from construction to automotive.

4. Adherence to International Standards

- Compliance with Global Standards: Iranian wire rods generally comply with international standards such as ASTM, ISO, and EN. This makes them suitable for export to a wide range of markets, ensuring that buyers receive products that meet recognized quality benchmarks.

- Quality Control: Iranian manufacturers often implement stringent quality control measures to ensure the mechanical properties, dimensional accuracy, and surface finish of their wire rods meet customer expectations.

5. Flexibility and Customization

- Custom Orders: Iranian manufacturers are often flexible in accommodating custom orders, whether for specific grades, sizes, or finishes. This flexibility can be an advantage for buyers with unique requirements.

- Quick Response to Market Demand: Due to the large production capacity and strategic location, Iranian producers can quickly respond to shifts in market demand, ensuring timely delivery and consistent supply.

6. Strong Regional Trade Ties

- Established Relationships: Iran has strong trade relationships with neighboring countries and key markets in the Middle East, Asia, and CIS countries. These established ties facilitate smoother transactions and often result in preferential trade agreements or reduced tariffs.

- Cultural and Political Connections: In some regions, cultural and political connections help strengthen trade ties, making Iranian wire rods more attractive compared to those from more distant or less connected suppliers.

7. Energy Efficiency and Sustainability

- Energy-Efficient Production: Iran’s steel industry has been investing in modernizing its facilities, including improvements in energy efficiency. This not only reduces costs but also appeals to buyers who prioritize environmentally sustainable practices.

- Focus on Reducing Emissions: With increasing global focus on reducing carbon footprints, Iranian producers’ efforts to adopt greener production methods can be an attractive selling point for environmentally conscious buyers.

8. Resilience to Market Fluctuations

- Government Stabilization Efforts: The Iranian government often intervenes to stabilize the steel industry during periods of market volatility, ensuring that production and export activities continue smoothly, even during global economic downturns.

- Diverse Export Markets: By exporting to a wide range of countries, Iran can mitigate the risks associated with dependence on a single market, making its wire rod industry more resilient to fluctuations in demand.

9. Strong Domestic Supply Chain

- Self-Sufficiency in Raw Materials: Iran has substantial domestic reserves of iron ore, which is a key raw material for steel production. This self-sufficiency reduces dependency on imports and protects Iranian wire rod producers from global supply chain disruptions.

- These advantages make Iranian wire rods a competitive choice in the global market, particularly for buyers seeking cost-effective, high-quality products with reliable supply chains.